It is sometimes hard to fathom how quickly technology enters and reshapes our lives; only 15-years ago, Apple’s iPhone did not even exist. If we’ve learned anything in the last year, it is that our businesses must quickly adapt and embrace technology to remain competitive. At the same time, we also must build sustainable practices into our business operations so future generations can enjoy the natural world’s beauty.

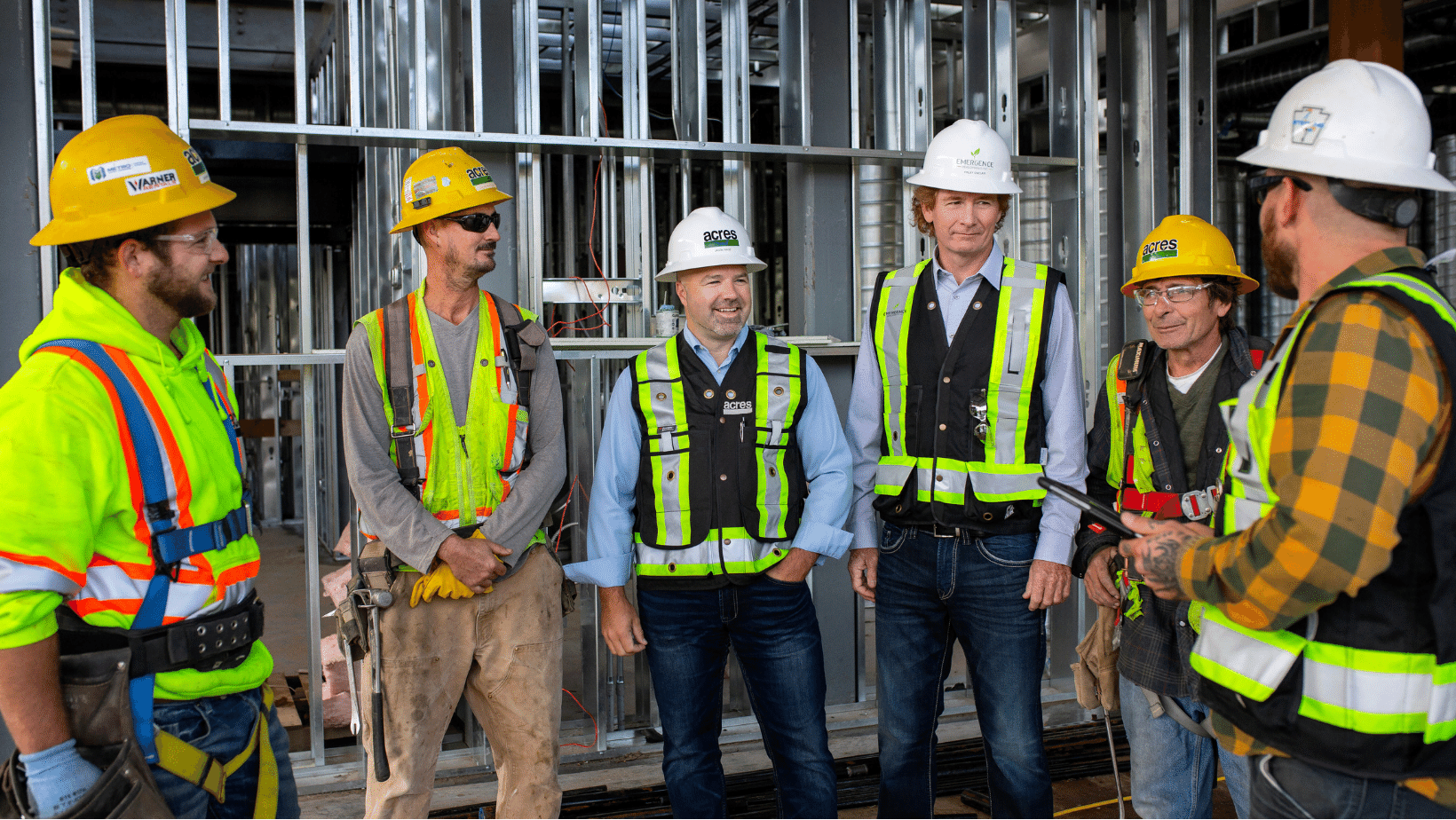

With a focus on what we are leaving for the next generation, Acres Enterprises is a homegrown industry leader in construction and development projects, with over forty years of experience in general, industrial and civil construction. Look around the city (and throughout the province) you will see Acres fingerprints on some of our most significant and complex projects.

We recently caught up with the President of Acres Enterprises, Jason Paige, to discuss his journey to becoming President, what he has learned along the way and how he and his team embrace new technology.

Jason, you started in the construction industry at the age of 16-years old. What is it that initially drew you to the industry, which eventually led you to become the President of Acres Enterprises?

I grew up working on a farm in a small town. My father was a welder, so he came from the blue-collar world and he was an entrepreneur as well. We always had houses and landscaping projects on the go, and when I was old enough, he asked me to partner with him. The first company we put together was Saber Bobcat Services. I had my first go at a logo, a company and brand when I was only 17 years old. My dad was a huge inspiration in terms of where I am now because he really lit a fire under me to always give my best. He showed me a different world – one that was different from the traditional go to work, punch a clock, do your thing, and go home. My dad showed me an entrepreneurial world. That’s what really sparked my interest and got me thinking, so I asked myself, “How can I get into this world?”

Well, I sold out of that multi-multi bazillion dollar company for I think two thousand dollars when I was 19 years old! I made a choice to go travelling, which also was a huge pivotal moment in my life. I had to learn a lot about acceptance and preconceived judgement that I had growing up in a small town. I had to break down those walls and barriers that I had previously, and I feel like I matured as an individual many years beyond my age.

When I returned home, I had a different motivation than most. Most of my friends had gone to university, or already had a career, and I felt like I was just starting out. I came back and felt a little behind in a way, so I really accelerated my way through university. Growing up on a ranch, I had the mentality that when the sun came up, it was time to work and then you kept going until the sun went down. It was pretty simple, and I learned that early on in my years, between raising our own animals and taking them to the chopping block and then feeding the family. I’ve always had deep independence and confidence when getting something done. It doesn’t take a lot to make something fly.

Now, fast forward to construction in 2003 when I joined Acres as a pipelayer on the ground. A combination of my work ethic and my ability to work well with numbers helped me work my way up through the ranks. I started on the side of a pipe, worked my way up to top man, and then I became survey hand running a grade crew. From there, I found myself in a superintendent position. I was fortunate to be given opportunities time and time again, and I always did something with them. In 2005, after I graduated from university, I started working in the office at Acres. I was working under Jim Laird – the previous director of civil construction and he took me under his wing. He taught me so much. I felt like a little sponge with my book, just furiously writing away every time he spoke!

Eventually, me being me and wanting to develop myself further, I branched out and started running projects on my own at the company. I was part of clean-up, where I completed deficiencies on all jobs, and eventually I started running the largest projects in the organization. I also created the industrial spaces. Before, we were mostly in general and civil, then I started bringing in mines and oil and gas jobs. Quite quickly we went from the smallest unknown department to the largest by far. We had grown that enterprise from zero to twenty-seven million in about three and a half years.

Now looking at where I am at today, I have handed off the torch to Phillip Stagg-Tanner, our VP of Operations to manage the industrial department and I have transitioned into the president role. I often wonder how the heck I ended up here, and it’s because of a lot of good people who I have been privileged to work with, and who have helped me along the way.

You studied Computer Automated Systems at TRU (when it was the University of the Cariboo College), how has technology changed the construction industry? How has it changed the way you tackle projects today?

I think if we look around, we would be silly to not understand how technology has changed the industry. In the 70’s we went through the industrial revolution, and now we’re going through the digital revolution. Since we’re currently living it, it’s hard to understand that it is actually happening. If you ever want to see it happening, just pull that smartphone out of your pocket. If you said to your grandma in the 70’s that you would have a device in your pocket that has more computing power than the supercomputer, and you can take pictures and videos, and do your banking and all these things that have become normal and available to us, she would have been in disbelief.

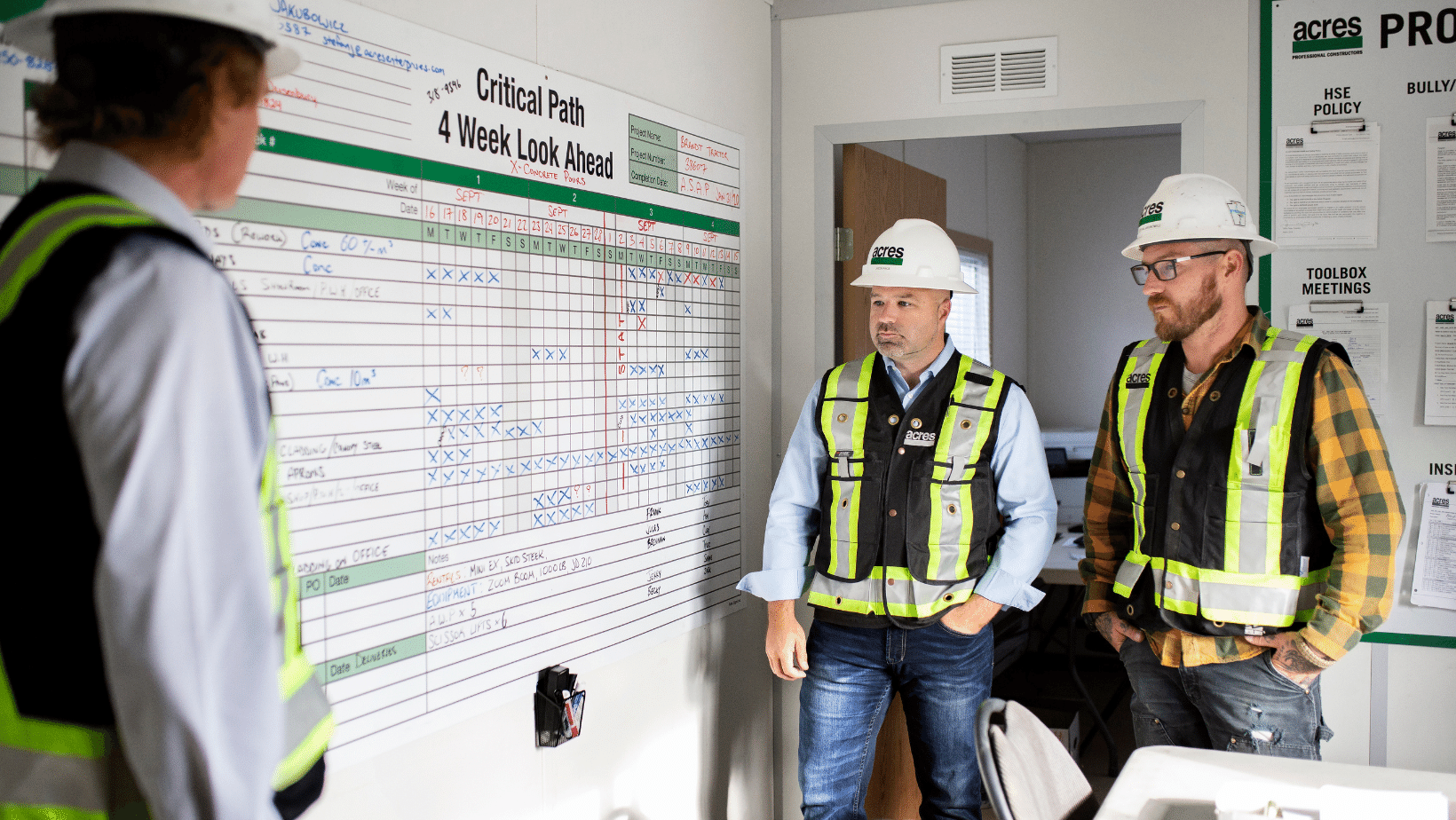

Construction is what I call a lighting sector and it is really dug in the ground. It’s difficult to change the way it’s traditionally been carried out. It’s largely because we have infrastructure in the office, and we have the infrastructure in the field and there’s a risk of those two nodes not acting and behaving the same. I think one of Acres’ unique identifiers is that we embrace technology not only at the corporate level, but also in the field. It takes commitment, resources, money, and time to get that all the way through.

The DNA of smarter, better, faster is how I’m built so it’s always something I’m pushing in our practices. This sector has not been approached with a continuous improvement lens, it’s been more about finding better people and doing the same thing we’ve done for 100 years, but just at a faster pace. It’s a very simple mindset. At first people were telling me I’m crazy about bringing in GPS drones and now we’re having meetings with companies because of our GPS utilization in construction. For instance, for a civil job at Predator Ridge, we took a two-year dozer operator, layered in our technology, and produced a product that no one had ever seen before. In the old days, we had to go and find an operator with fifteen to twenty years of experience, get him a Cat that he knew how to run and then let him do this thing for a couple of weeks. Not anymore. Now, we put a 3D file into the cloud, download it into an automated machine and the rest is done for you. The product we are producing for clients is value-engineering – it’s providing value to their businesses, and I know there are many more opportunities for us to keep repeating this model.

Photo Credit: Acres Enterprises

Photo Credit: Acres Enterprises

You can see Acres work across the city, from TRU to the Kamloops Courthouse, what project are you most excited to tackle in 2021? Why?

I love any project that is at its infancy. I’m finding that our team is really good at tackling the concept to completion model. I always knew our group had extra to offer and combined, we have 600 years worth of construction experience. I mean, that’s awesome, but how does that really benefit our clients? How do we take our brains, experience, and collective know-hows and push it into the design to provide value?

This is why when we bring clients in and they have a piece of dirt and are excited to do something, I get just as excited because I think, here’s our chance! We get to go from beginning to end, and that whole concept to completion approach allows us to double up where the client’s business is and put it in our focus. At Acres, we know you’re selling things and if we help you by bringing it to market sooner, making it look better, and using our brains to figure out how to value-engineer that design, then we don’t have many hiccups along the way.

We have a really unique approach to construction. A lot of teams want to get calls when a project is ready to bid. They go hire their design team, and they figure out what they want it to look like, then they take it to market. We can do that of course, but what really excites me is when we can bring our building team in, and then an engineer makes a suggestion that in turn takes weeks off the schedule. That’s the difference between bringing your product to market in August when it sells best, versus in November when people are busy for the holidays.

Photo Credit: Acres Enterprises

Photo Credit: Acres Enterprises

Sustainable business practices are increasingly more important as we combat climate change around the globe, what is Acres doing to tackle sustainability when taking on a project for clients?

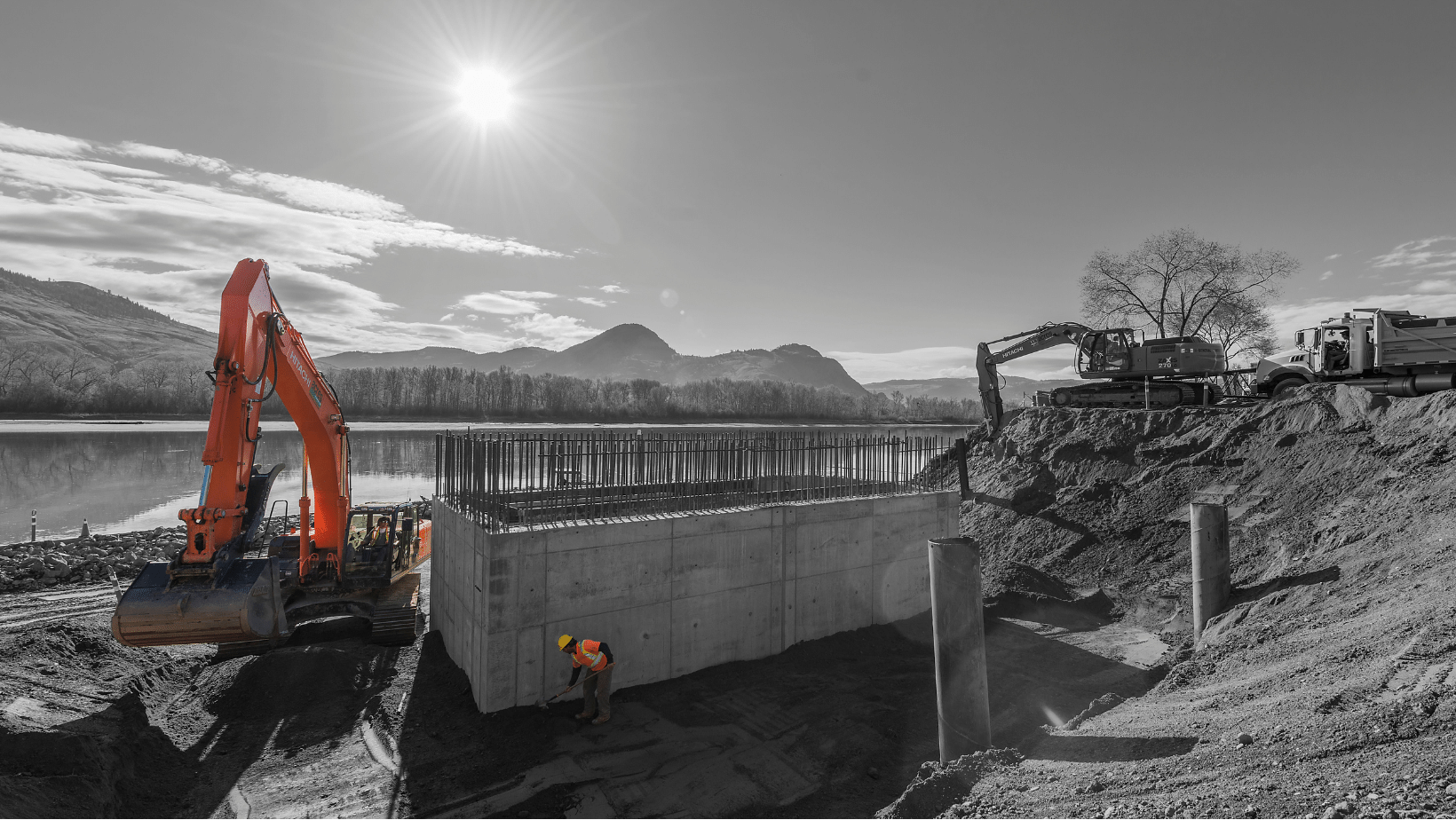

Construction can be one of the most wasteful industries, and it really excites me when we can minimize waste. One of the best examples is from a reservoir we worked on when I was a project manager. In the old days, it was standard to buy the lumber, cut it all up, stick it on the walls, pour the concrete, then leave. Then, we did this project using PERI formwork. I remember doing calculations and realized that not only did we do the job faster, we had a product we could use without taking so much out to the dump. That formwork is actually steel formwork, so it has exoskeleton, with a plywood front piece, so every so often you just have to replace the plywood. In the old days, truck loads and truck loads of wood would go to the dump. It was like, one use, then goodbye! On a large project, you might have one or two uses. With our PERI formwork technique, you get years out of it, if it’s being taken care of properly. There is an example that shows that not only can we bring efficiencies to the table, but our waste footprint just goes significantly down.

The civil contracting model is another good example. Moving dirt twice uses more fuel and oil. When you do the job once and you do it right, you compress your schedule and your carbon footprint gets reduced and you’re way more efficient. The spinoff on that is that you’re not wasting product. Another thing we do is simply turning the equipment off, rather than idling for too long. It started with an economic lens, but really, you get the carbon footprint down.

Photo Credit: Acres Enterprises

Photo Credit: Acres Enterprises

We’ve briefly talked about how technology has changed construction, what predictions do you have for the future of the construction industry?

I think we’re going to see market leaders emerge in a big way over the next three to five years. If you look at some of the major players right now, they’re looking for offsite, modular construction. Robotics are in the technology field, BIM – building information modelling is being used in a big way, and HoloLens and any 3D augmented reality components are coming at us hard and fast. We’re going through something similar to the evolution of the phone. You know, the big battery pack and antenna! You’re seeing that happen to construction in real time. I think those companies that embrace it are untouchable. There’s a law in the electronics world called Moore’s Law, which is an observation trend that states every two years, things double. They get faster and smaller and the speed and storage of the technology is doubling. If you ever look at your SD card or your old USB sticks, they go from 8 megabytes, to 16 megabytes, then 32, 64, 128, 256, 512, 1024, and so on. In a very short period of time, you’ve doubled your capacity. I remember when I was in Japan, I was looking at an SD card, and at the time, I had never seen an SD card that goes in a camera and it was 8 megabytes and I was just astonished. Now, we laugh at that. We have terabytes in a hard drive. It can be hard sometimes to comprehend the exponential power of technology. I embrace these changes though. I’ve seen it in real time, I’ve seen factories, and conveyer systems go from an efficiency of 25 percent to 95 percent. Instead of putting two boxes on the conveyer belt, they changed a few motors, put in a few robotics and all of a sudden, it’s ten times faster. I think companies that see that and embrace that, will never look back. Companies need to leverage that technology or risk being far in the dust. I’m happy with where Acres currently is with leveraging technology. We have all the tools, and a team investing in it.

What is your favorite thing that you tell out-of-town guests to discover when visiting the River City?

I love that I can rock my cowboy boots and head up to my ranch. We have the perfect blend of city amenities, but a wholesome culture that is hard to replicate. When I go to larger cities, I always look forward to coming back home. In Kamloops, you’re comfortable being you. We’re sophisticated enough of a marketplace that we have everything we would ever need, but we’re not too far beyond our bridges. It feels like home. Since I grew up in a small town, this is the perfect sized city. Aside from the beautiful golf courses, Kamloops gets the most hours of sunshine in the entire interior. When I travelled, I thought for sure, I would never settle in Kamloops, but I will never forget this one day, when I was coming down the hill after a visit to Vancouver. The sun was shining, you could see the lake on the left, and it was a bluebird sky. I had a sense of euphoria come over me. I just took a deep breath, and knew I was home.

Jason and his team at Acres Enterprises are committed to delivering excellence through the cutting-edge use of technology and providing quality builds that stand the test of time. Learn more about the Acres difference here.

To connect with Jason Paige on LinkedIn, you can do so here.

Contributing Author:

Nic Zdunich,

Community Builder,

Kamloops Chamber of Commerce